Specialising In -

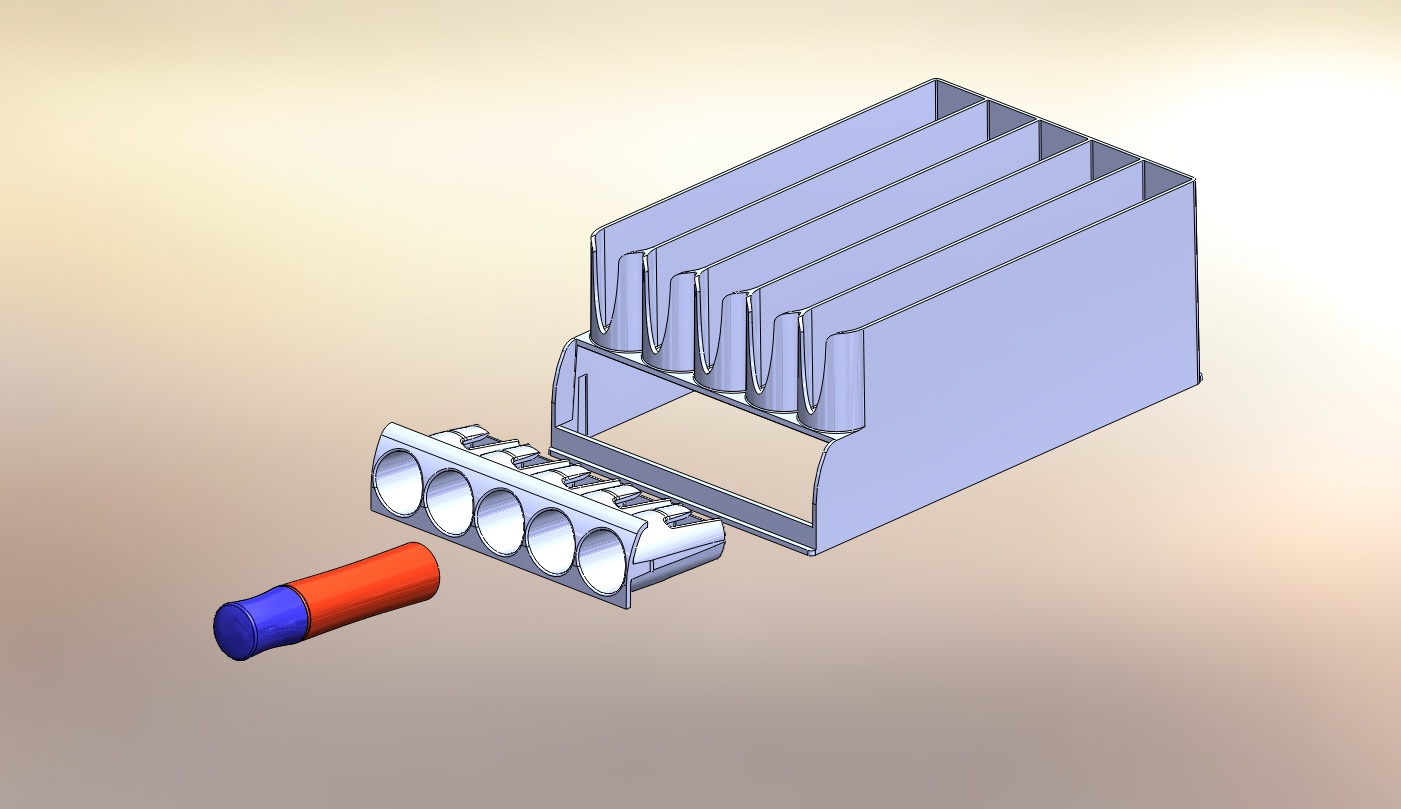

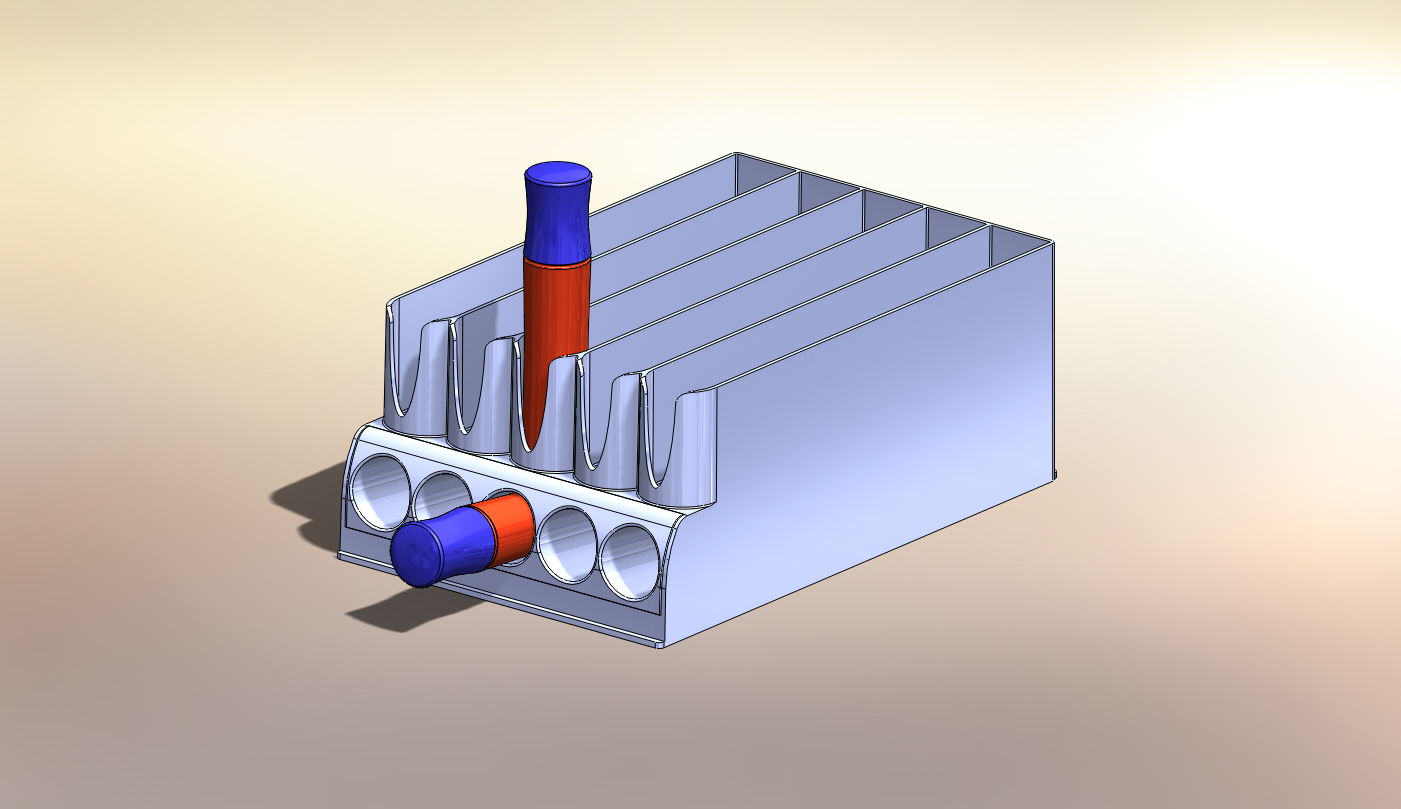

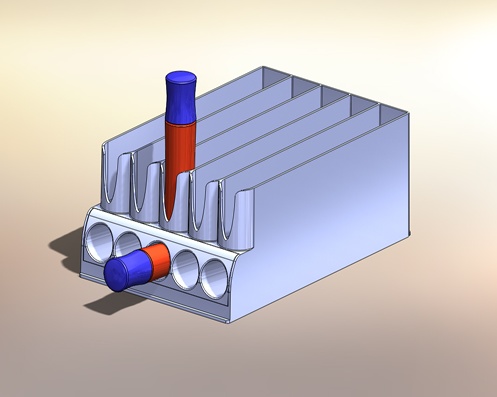

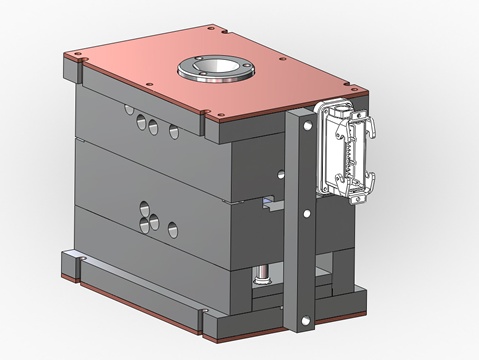

Injection Mould Tool Design

Plastic Part Design &

Development

Product Design

Tool Design

RMG Design are well suited to Plastic part design and development. We can work from initial sketches, prototypes and ideas to meet the vision of the client while maintaining a mouldable part 'fit for purpose'. Our senior designer has literally designed 1000+ injection moulded parts for the POS industry alone.

While keeping the clients vision we think forward to the tooling. The bottom line is to design a product / assembly that does what the client wants but ensuring the tooling will be economic to manufacture. A prime example is avoiding undercuts unless really necessary. Just as importantly is designing products that will help keep the tooling reliable in production.

Key Areas Of Our Product / Part Design Knowledge

- Develop From Clients Visuals / Protypes / Ideas / Sketches.

- Engineer Existing Data Into Mouldable Parts.

- Polymer Advice / Selection.

- Design Correct Drafts / Shutout's.

- Best Method Of Assembly - Clips, Sonic Welding, Peg & Hole, Push Fit, Glueing, Etc.

- Design The Assembly Method Into Parts.

- Feed Point Advice / Selection.

- Trial Moulding Evaluation & Modifications.

- Design Other Parts Such As Extrusions & Vacforms.

Copyright 2019 RMG Design

Tel - 01530 831066 Email - sales@rmgdesign.co.uk